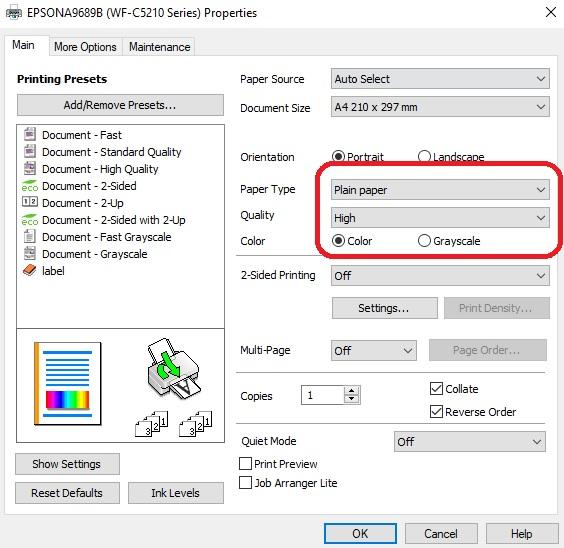

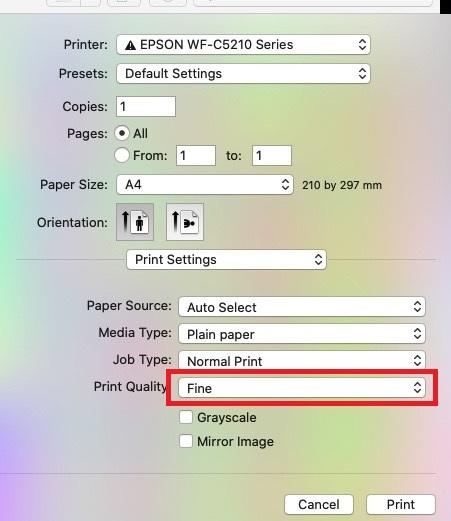

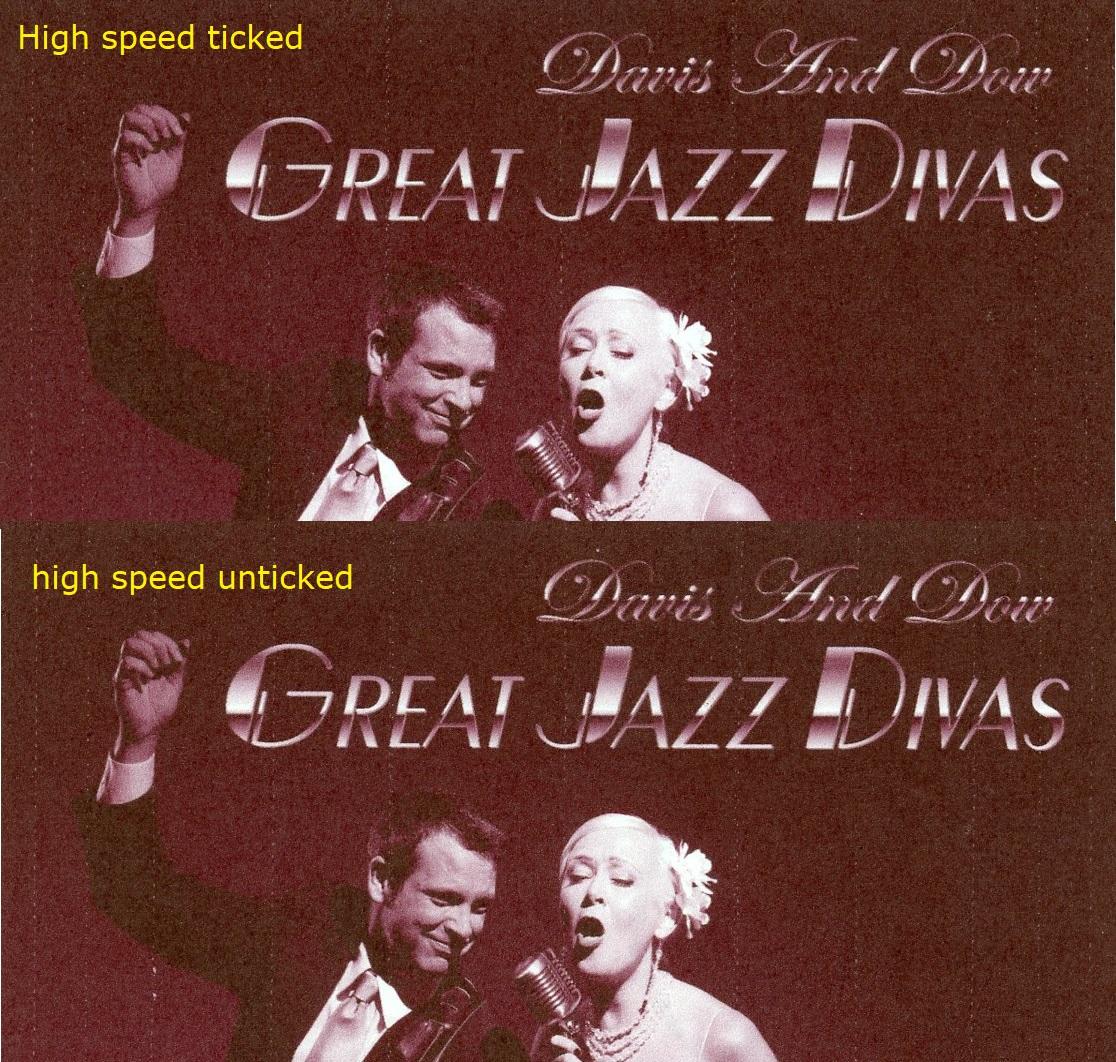

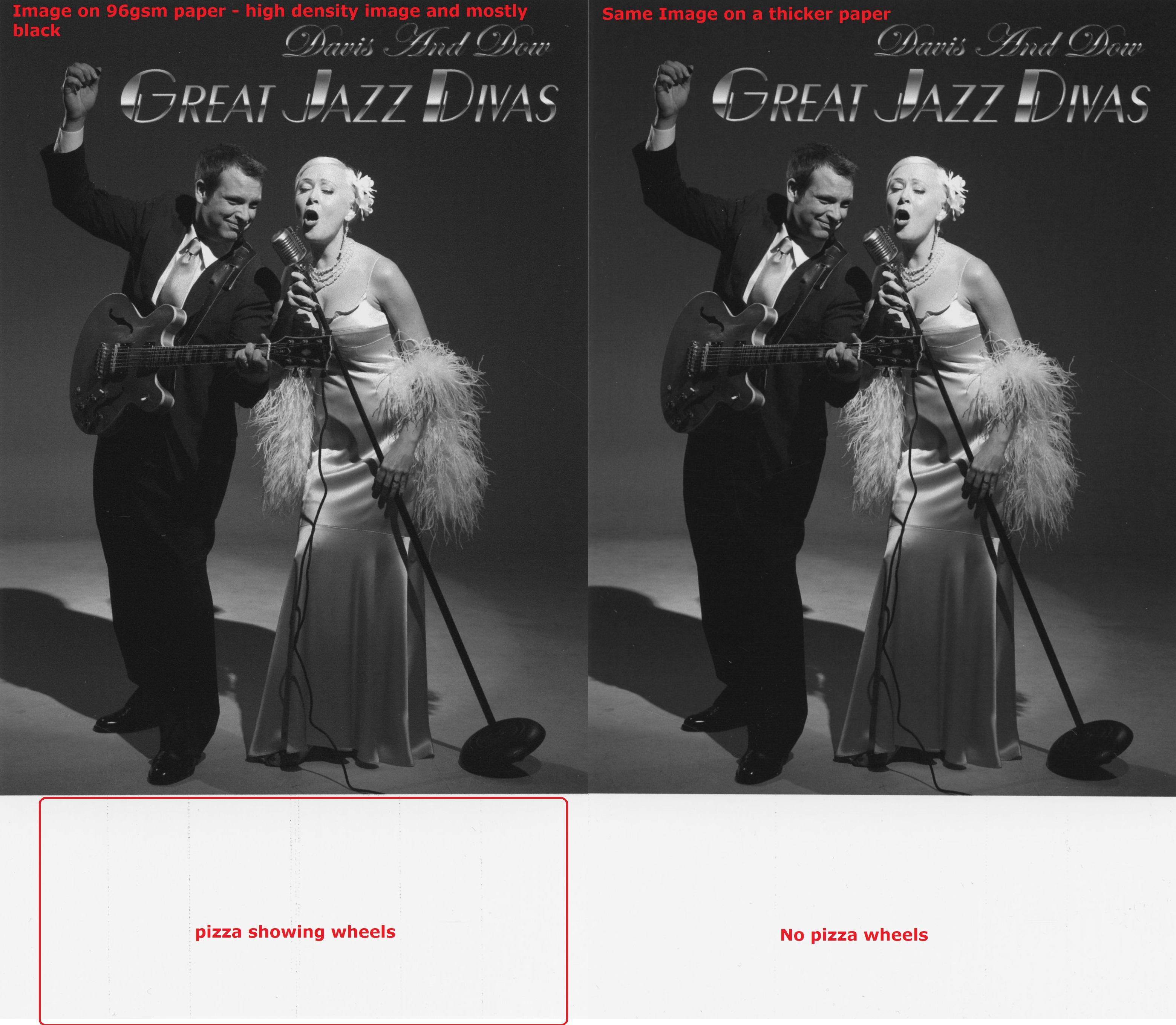

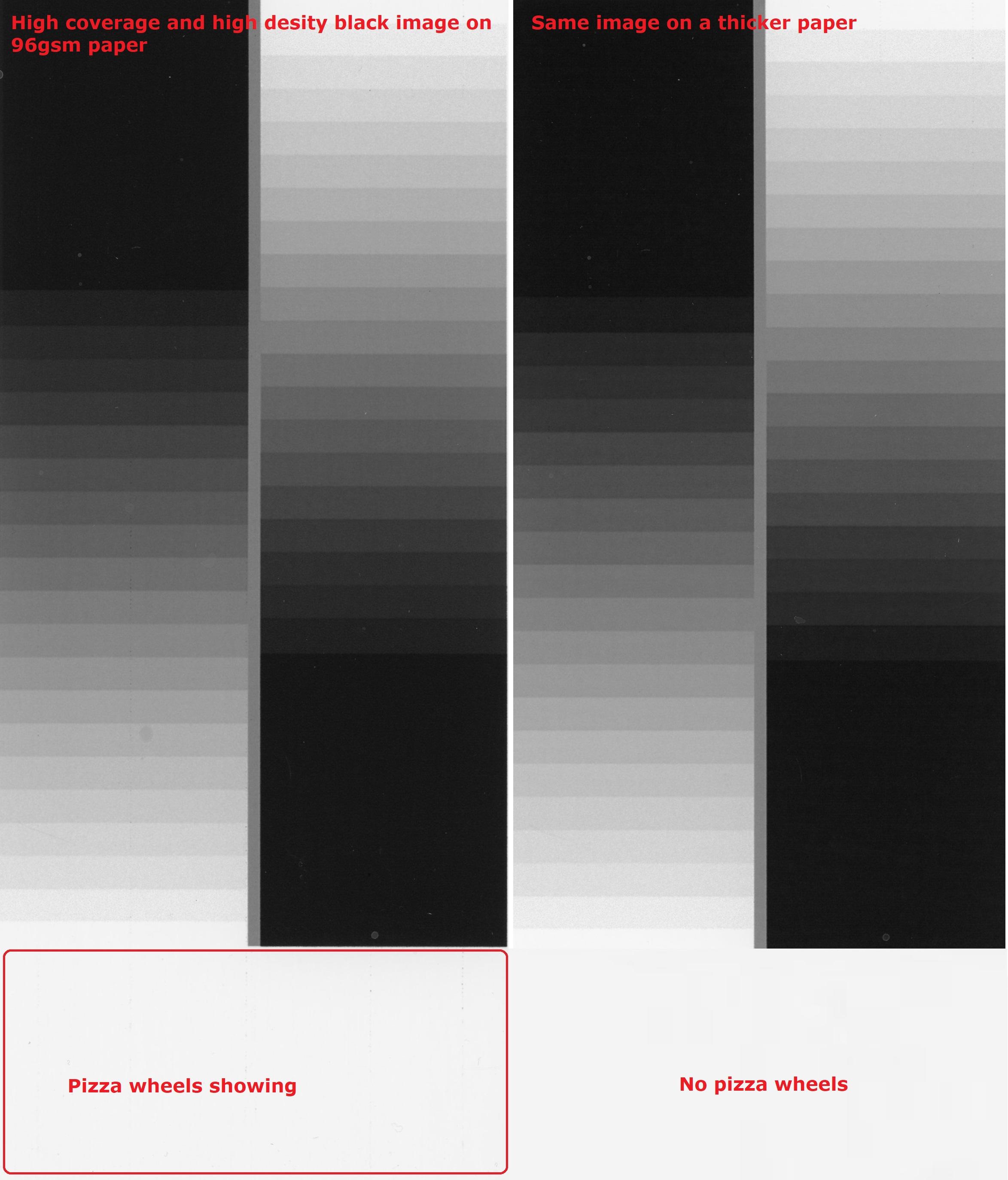

For Our Examples we have chosen - high density pure black images as these tend to show pizza wheels more than anything else - windows at the top - Mac at the bottom

Printer Settings paper type and print quality

For our own papers we recommend plain paper high quality setting apart from the Epson L805 which is matte standard - using the wrong print quality setting can apply too much ink to the paper and it wont be dry when it hits the rollers.

For Mac it will say Quality - or Fine depending on the model.

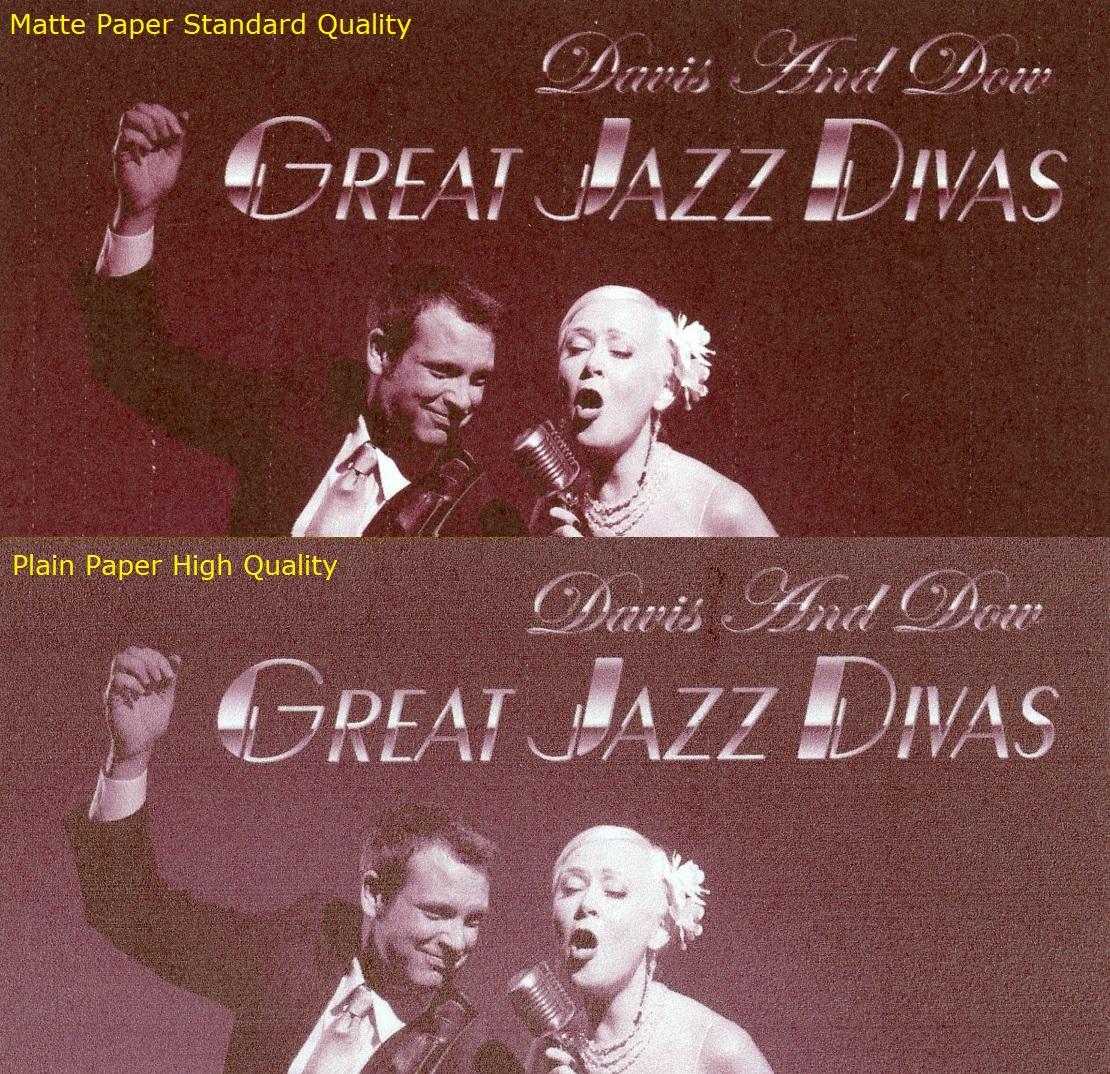

These images show plain paper high quality and matte paper standard quality and the difference in results with regards to pizza wheels, these are printed - scanned - un-sublimated images.

although still present on the plain paper they are much improved and when the pictures is sublimated they may not show on the finished product due to the heat activation of the ink. One thing to bear in mind in changing your print quality setting is the icc Profile will of been built around a particular print quality setting so if you change to something different than what your manufacturer / supplier recommends - your outputted finished result can be affected..

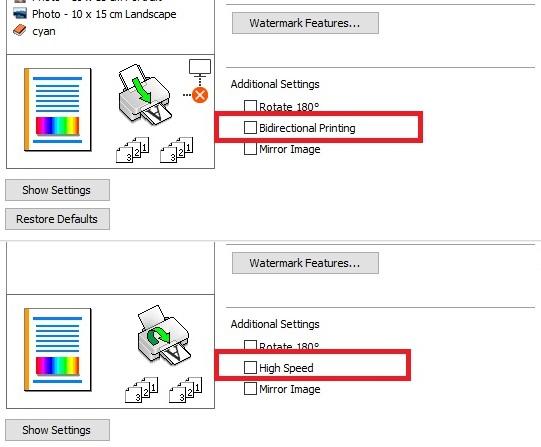

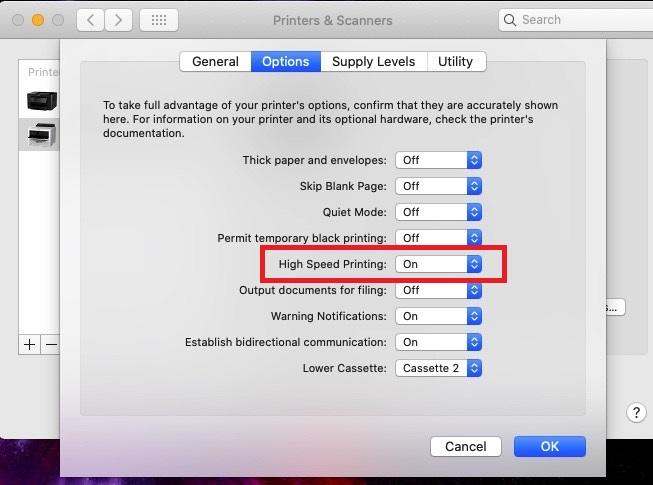

Printer Settings - Print Speed

Other settings also in your control which you can check and change - is the print speed setting - if high speed printing is selected the ink wont be dry when it hits the rollers - in this image density / colour there is only minor improvement.

settings can be found in the printer properties

For Mac it's in system preferences - printers

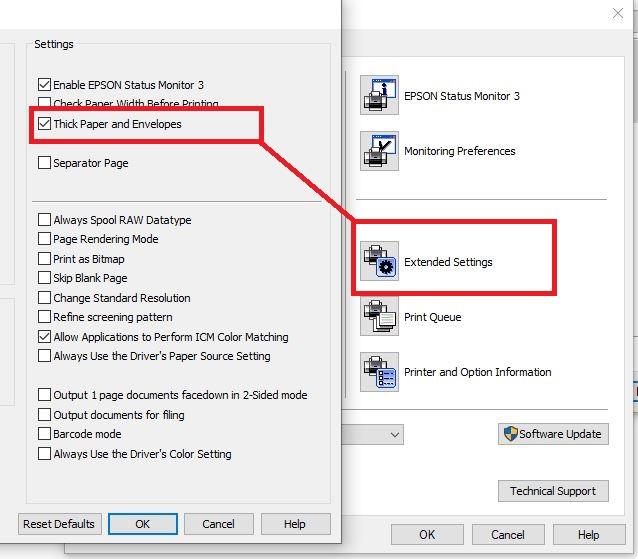

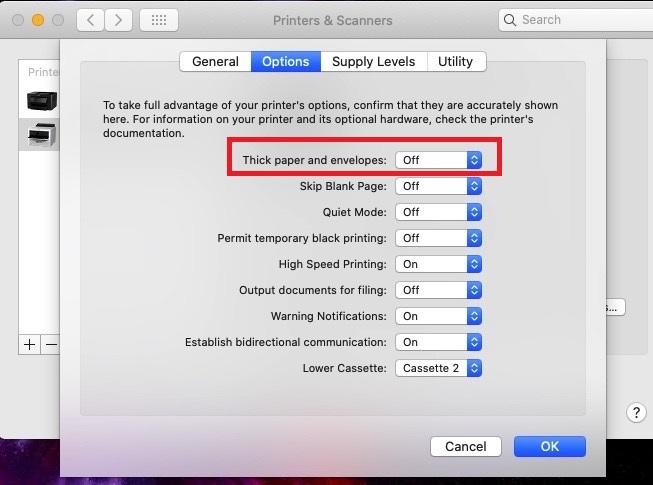

Printer Settings - Paper Thickness

Another setting that may effect lines is the paper thickness selection which is only available on some printers

In windows if available it's in printer properties - extended settings

For Mac it's in system preferences - printers

With thousands of paper types on the market ranging from just 90 GSM to 135gsm for sublimation printing its possible to get Pizza Wheel marks on any paper when used in conjunction with a certain media thickness , image density , versus printer settings.

It's easier to get pizza wheels on thinner papers or high release papers which typically release more inks which is good for fabrics so you need to work out what settings work out well for your paper / printer / image combination .

Recommended settings are generally given by your supplier but things can change over time even a more saturated image can cause issues

If you have developed Pizza Wheels it does not mean you have a faulty printer, ink or paper here are some examples of why you may need a thicker paper.

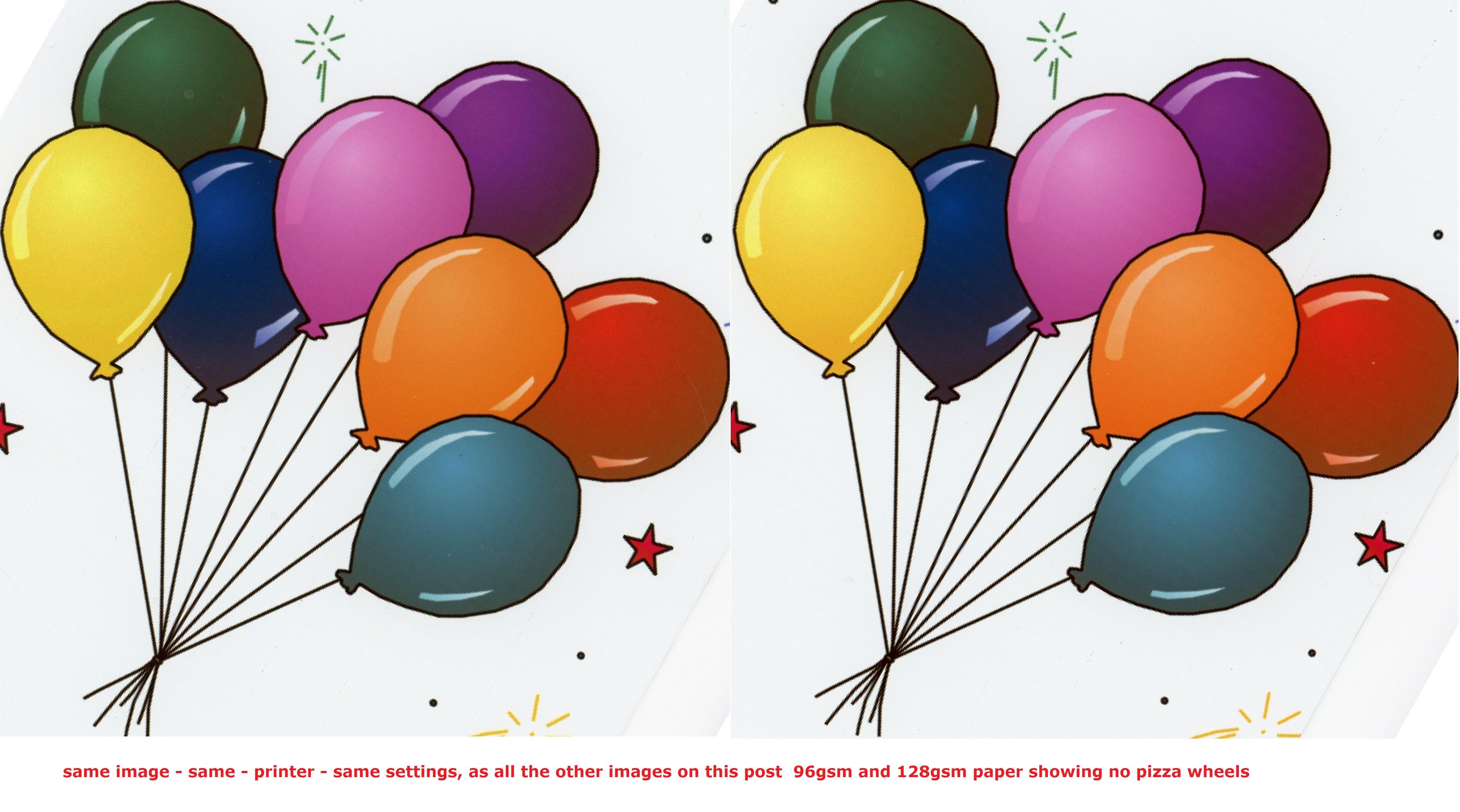

This image is printed on 2 different brands of paper but with the same printer and settings - the one on the left has pizza wheels the one on the right does - so from this you might say ok the paper is faulty - in this case you are wrong - look at our second image of the balloons.

Our second image same settings / paper / printer again but no pizza wheels ? - this is because the 1st image is very high density for the paper type so it needed a thicker paper also black inks generally are the colour that can show on pizza wheels.

During more tests with different brands of paper similar issues were found - again this one with blacks.

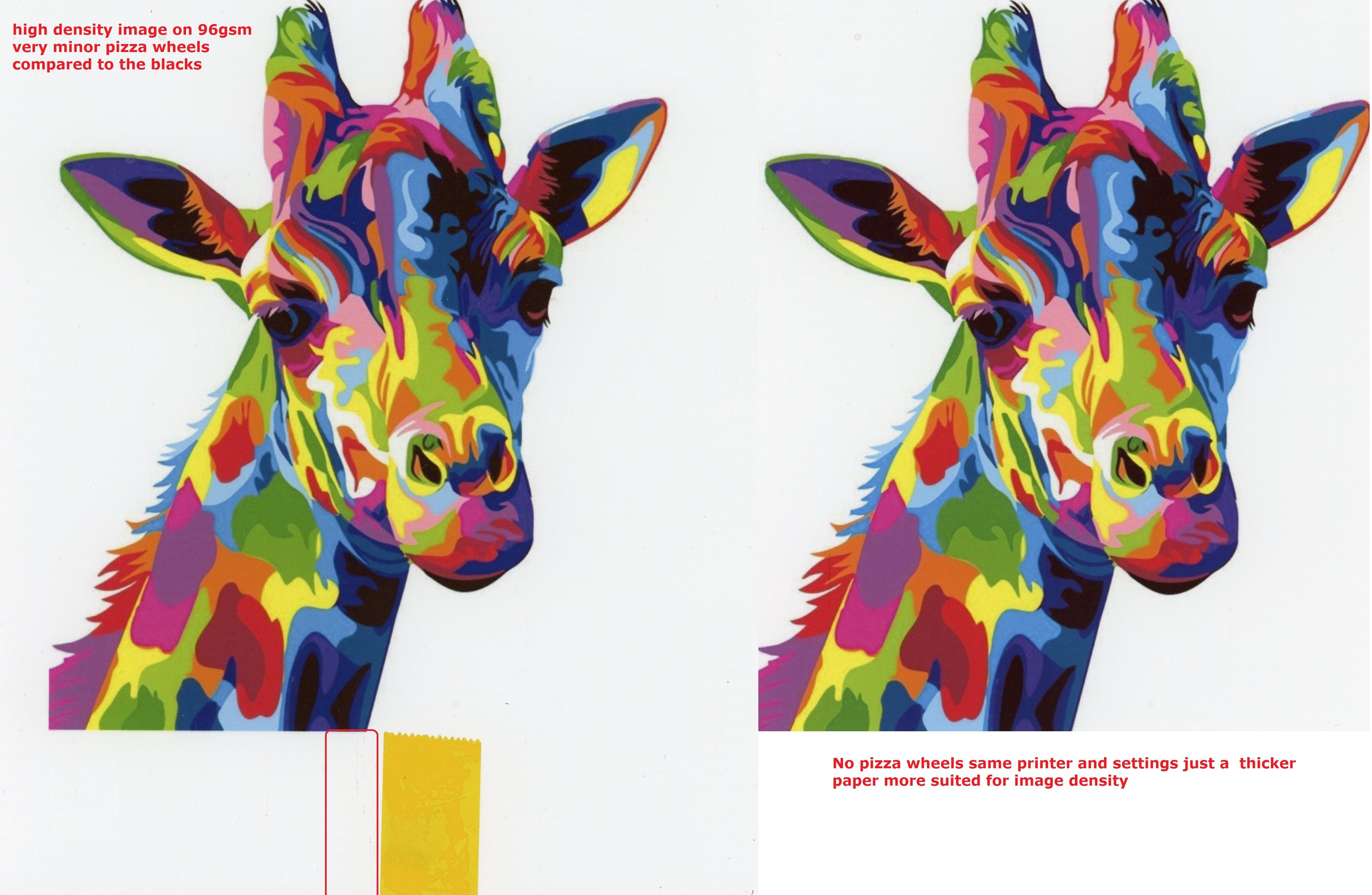

This one is a high density colour image which showed the same - although very minor on thinner papers

so in summary occasionally you may need a thicker paper / quicker drying if your image is very dense, although we recommend this is as a last resort as it may increase your costs, other solutions are possible which include changing printer settings and cleaning the feed rollers.

Some of the papers we tested are shown below

So this is our 1 st post in a series of dealing with Pizza Wheel marks in sublimation printing

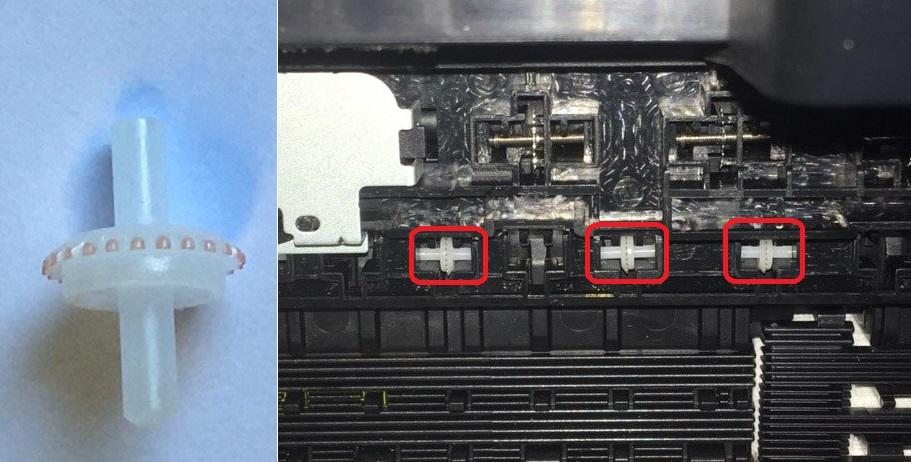

Pizza wheels are small dotted lines which can appear after printing, after pressing or both and are caused by the paper feed rollers at the front inside the printer

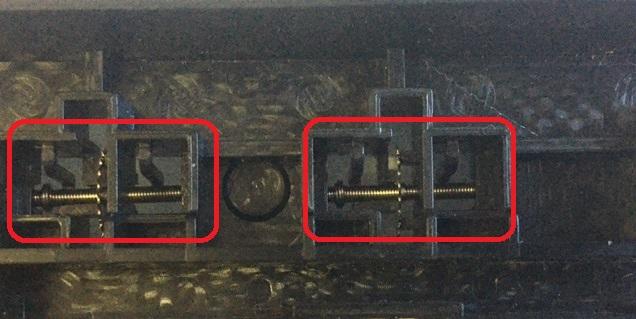

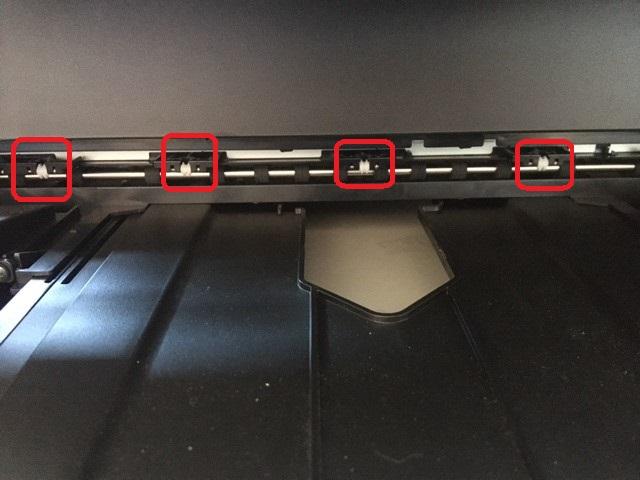

This is a typical plastic feed roller

they are always located at the front and inside the printer - You also have metal feed rollers inside but generally speaking these don't cause any issues

The plastic feed rollers should not be be confused with ones that maybe seen outside when standing in front of the printer like below

Things that can attribute to these wheels marks and how you solve them are

1 Printer settings -

2 Image type and density

3 Moisture

4 Paper type vs steps 1-3 above

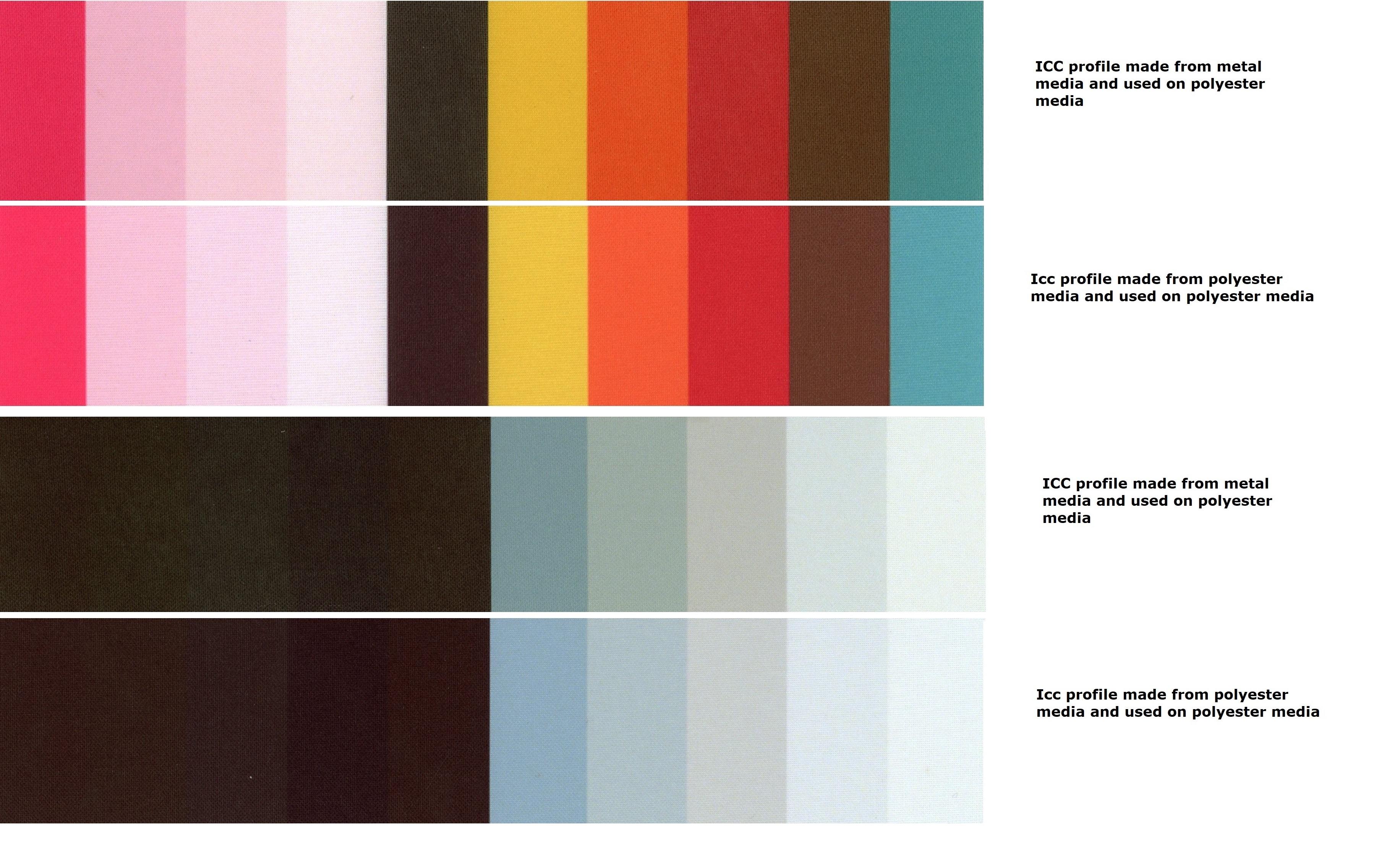

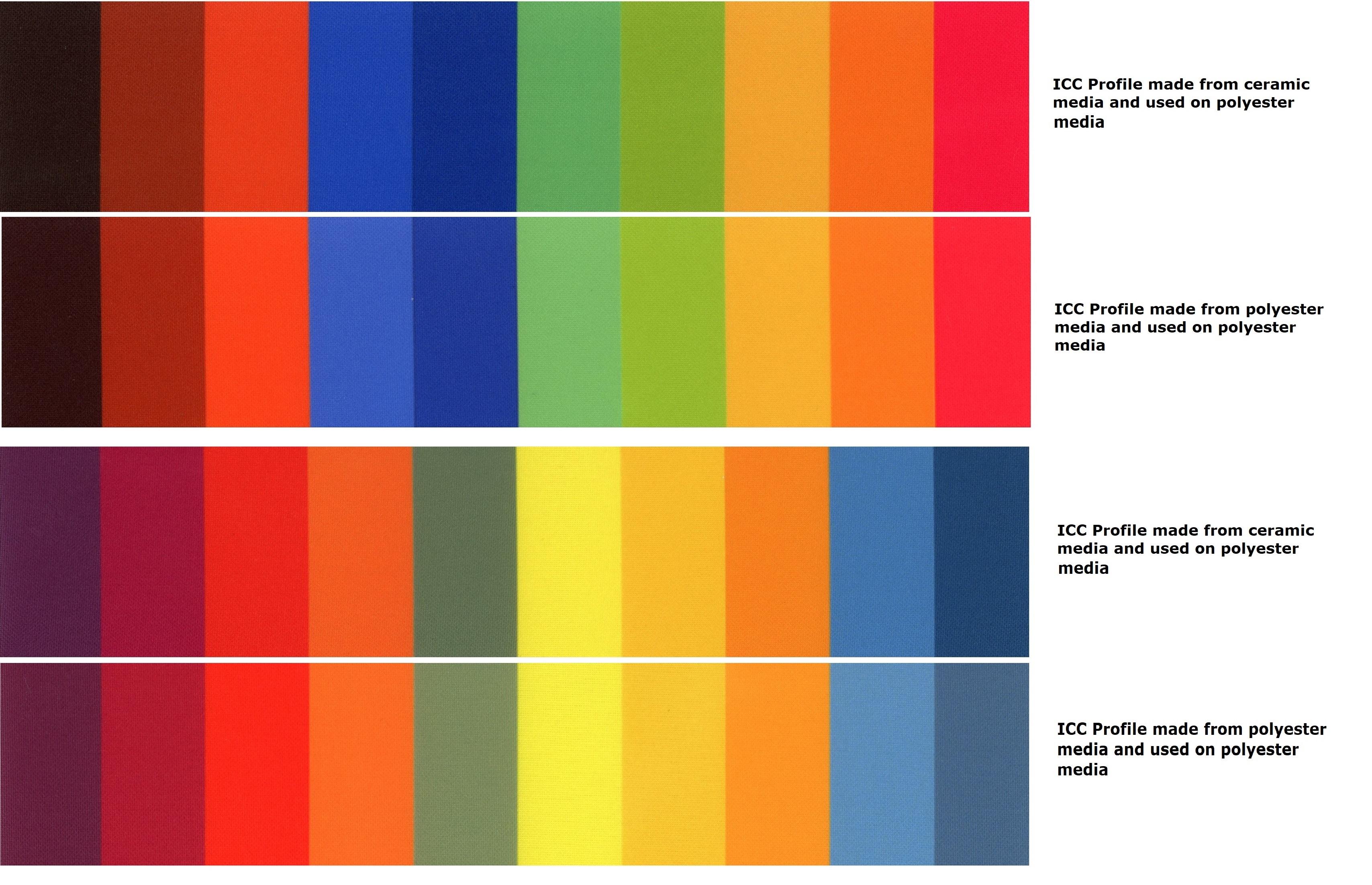

Sublimation ICC profiles are created by scanning the media after sublimation for more accurate colours

Why would you create an ICC profile from an item sublimated on polyester then use that profile when pressing on a different media type ?

A wider range of tones and closer match to the original colours is achieved by using an ICC profile created around the media type you are pressing - custom icc profiles are better if you are trying to colour match a specific design.

ask yourself these questions

1: If you have an icc profile what was it created from ?

2: Are you using it on the same or similar media type ?

3: Are you getting the best results you can from your current setup and supplies ?

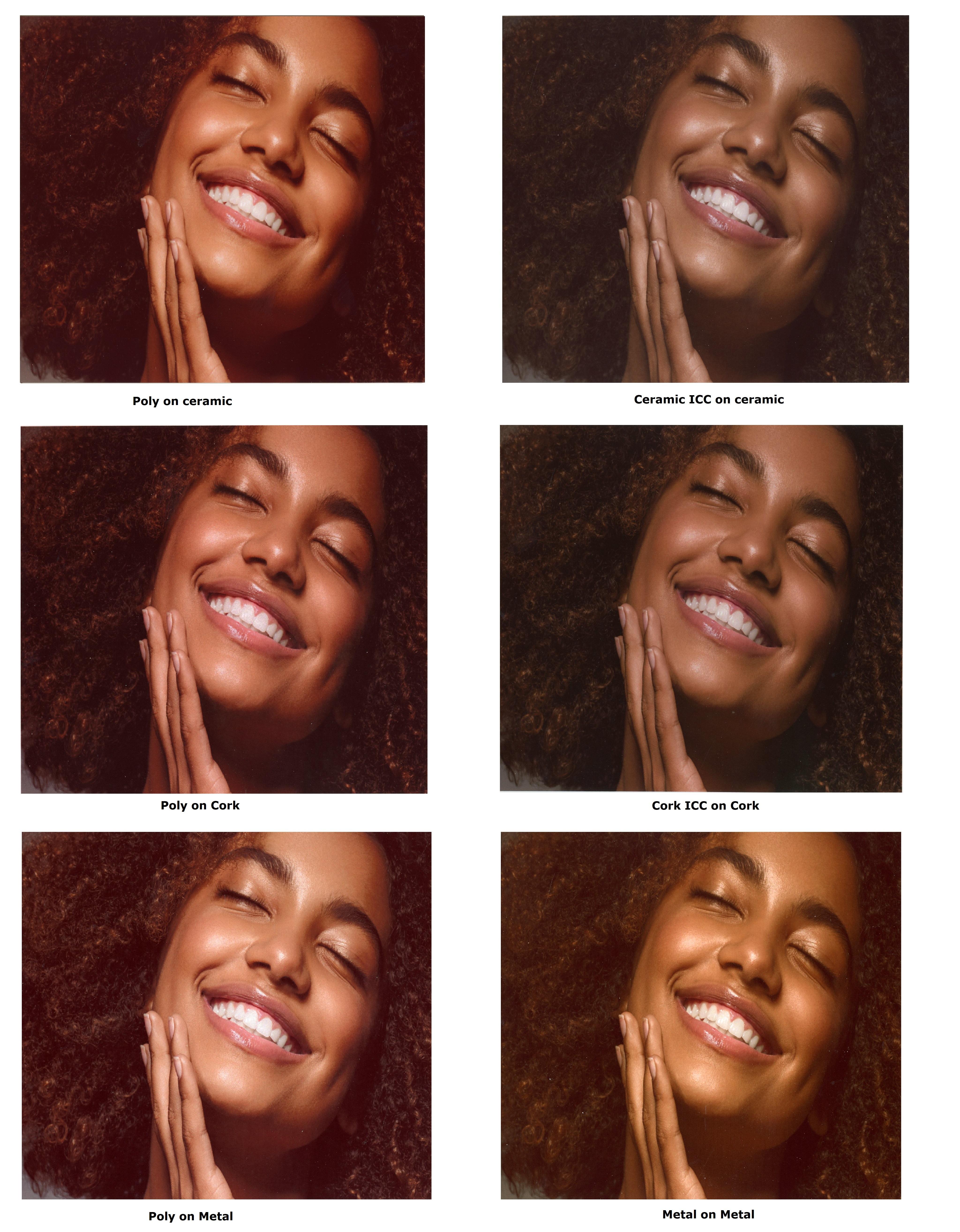

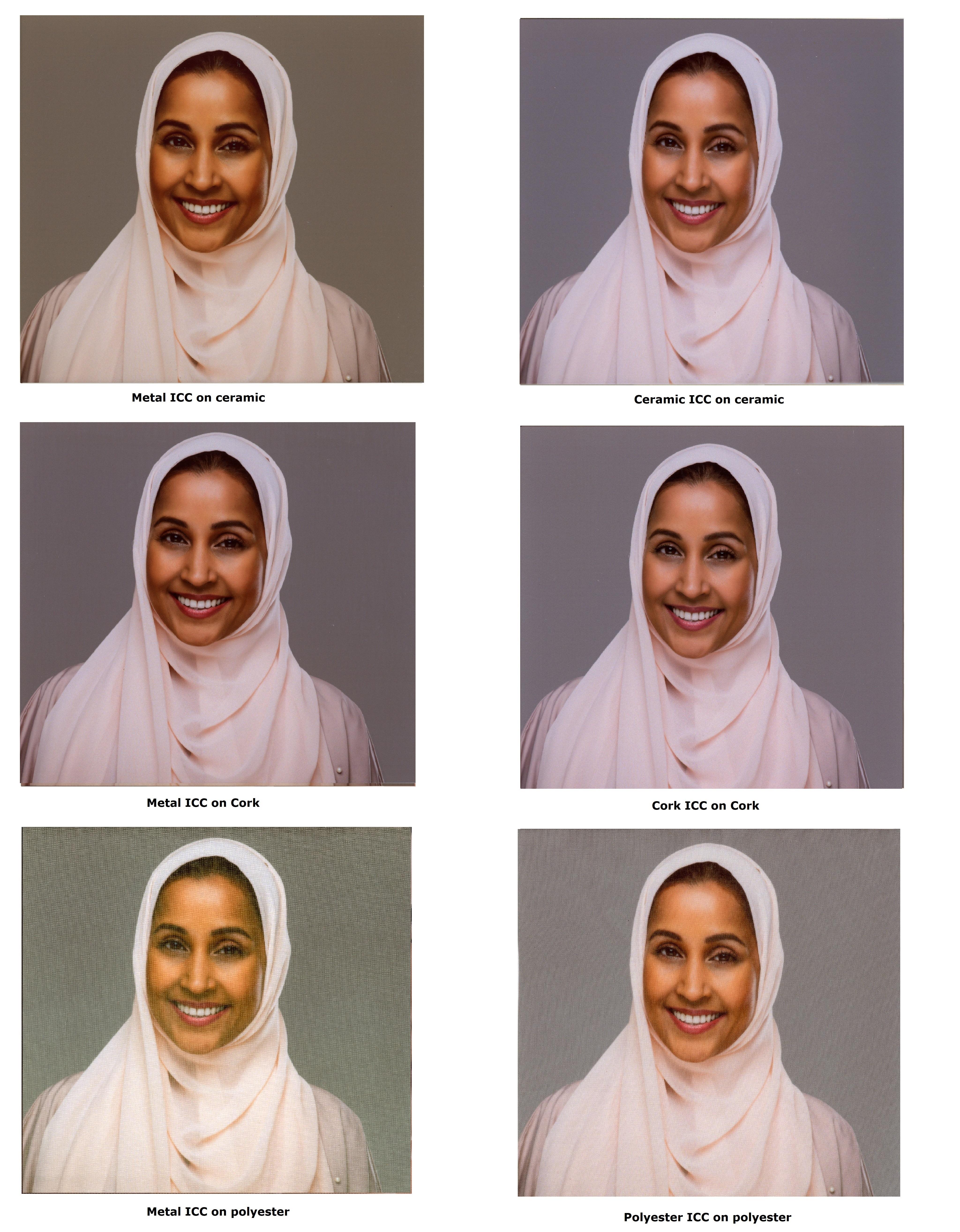

Here are some examples of some images that have been sublimated onto products and then scanned into an image file

The source ICC profile was made on metal then we used this profile on other media types and then compared to an icc profile made around the specific media type.

The images do show what we expected - but please bear in mind these are sublimated scanned images - looks much better sitting here looking at the physical products.

TEST 1

For our colour test charts on this one we are using a using an icc profile created from polyester media on ceramic media

TEST 2

For our colour test charts on this one we are using a using an icc profile created from polyester media on an aluminium sheet

TEST 3

For our colour test charts on this one we are using a using an icc profile created from polyester on a cork / mdf item

Sublimation ICC profiles are created by scanning the media after sublimation for more accurate colours

Why would you create and ICC profile from an item sublimated on metals then use that profile when pressing on a different media type ?

A wider range of tones and closer match to the original colours is achieved by using an ICC profile created around the media type you are pressing - custom icc profiles are better if you are trying to colour match a specific design.

ask yourself these questions

1: If you have an icc profile what was it created from ?

2: Are you using it on the same or similar media type ?

3: Are you getting the best results you can from your current setup and supplies ?

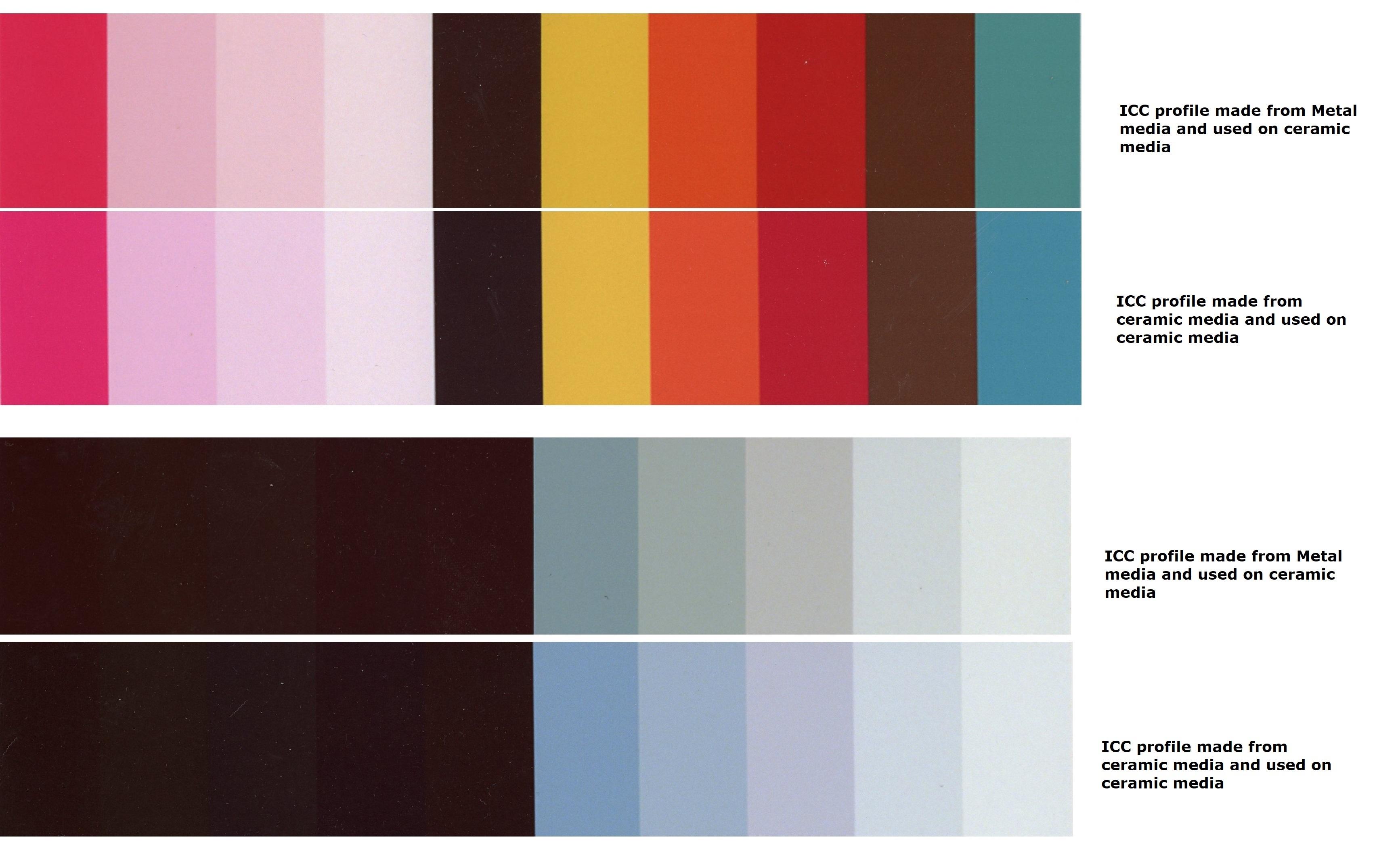

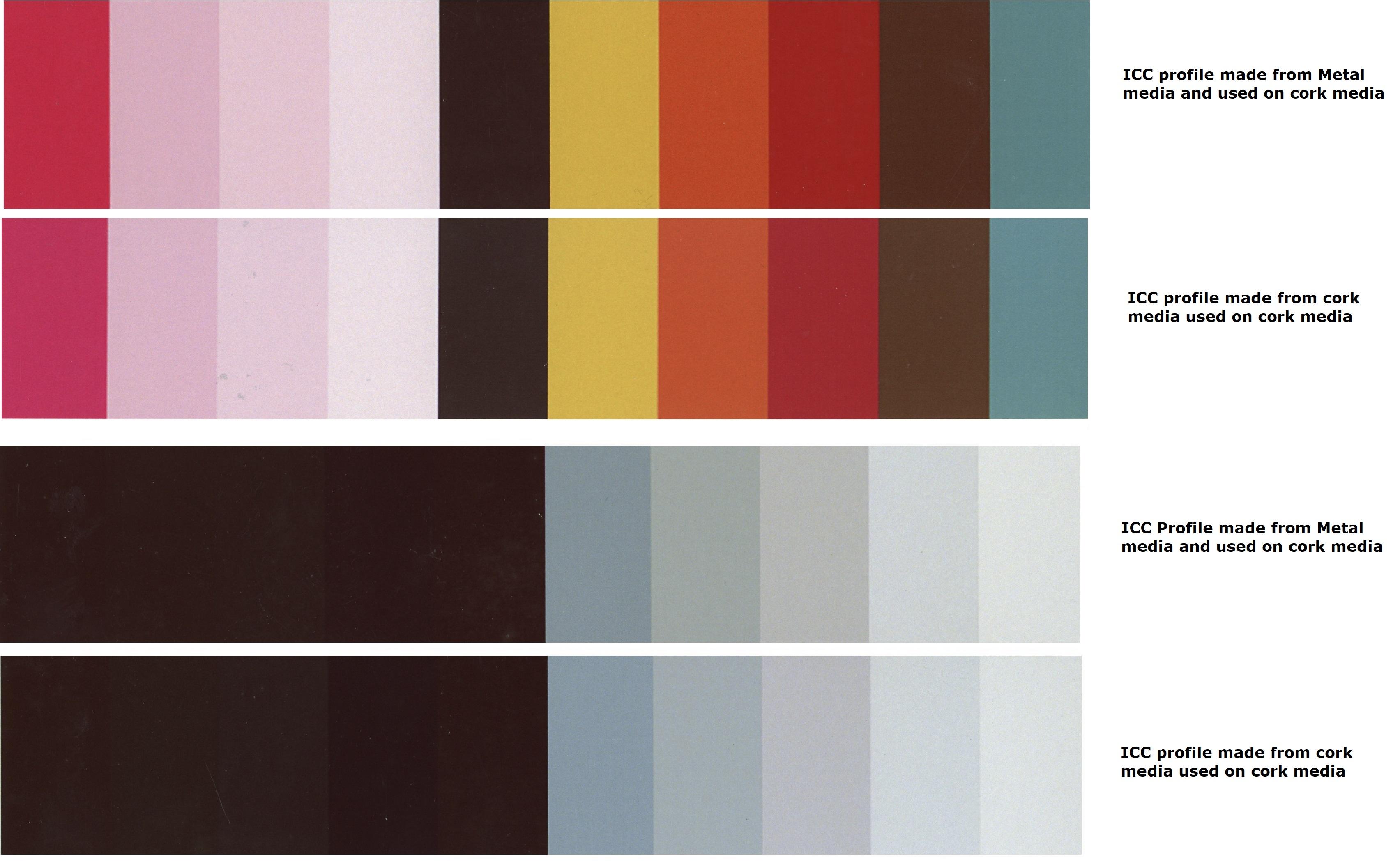

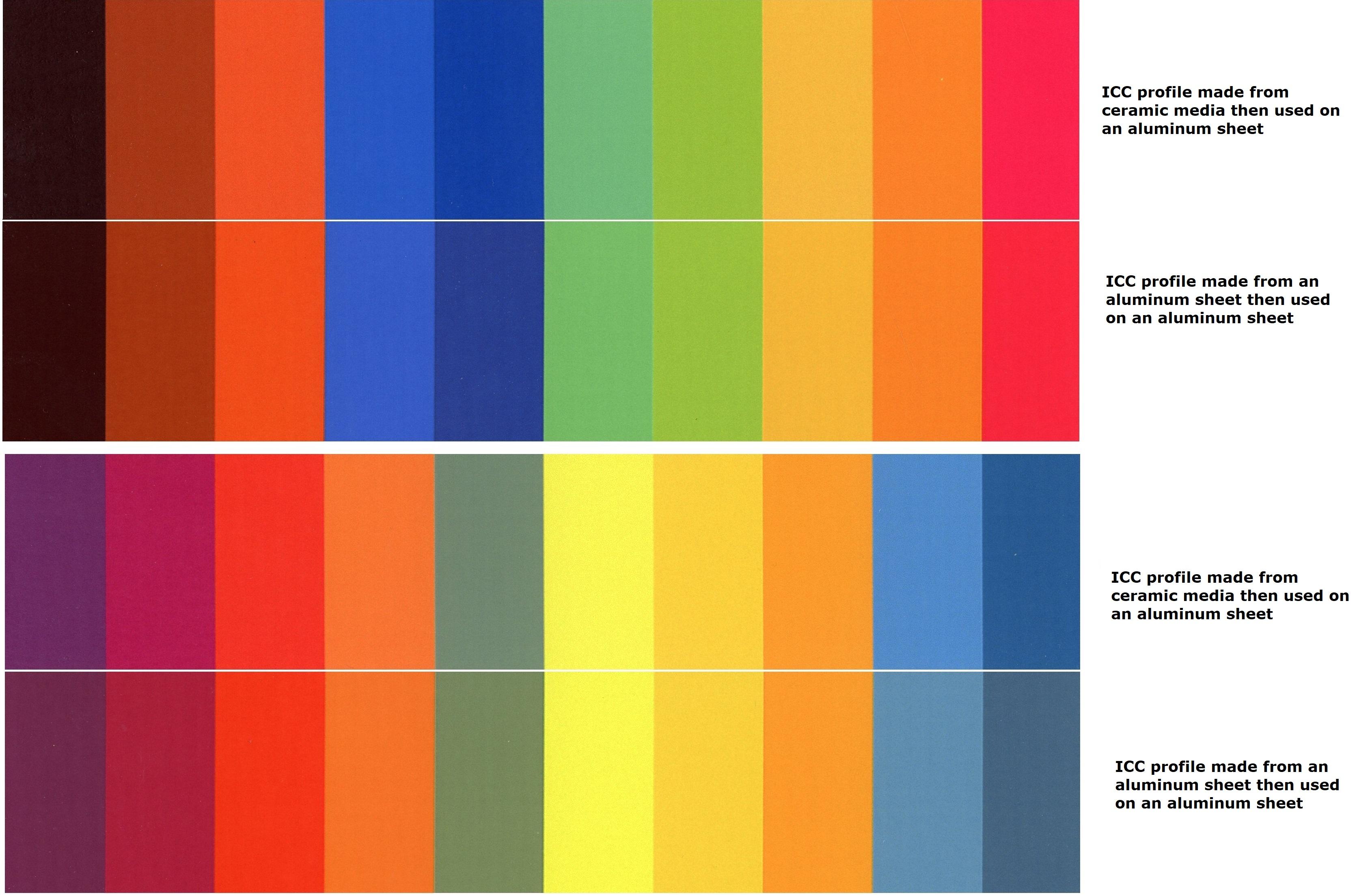

Here are some examples of some images that have been sublimated onto products and then scanned into an image file

The source ICC profile was made on metal then we used this profile on other media types and then compared to an icc profile made around the specific media type.

The images do show what we expected - but please bear in mind these are sublimated scanned images - looks much better sitting here looking at the physical products.

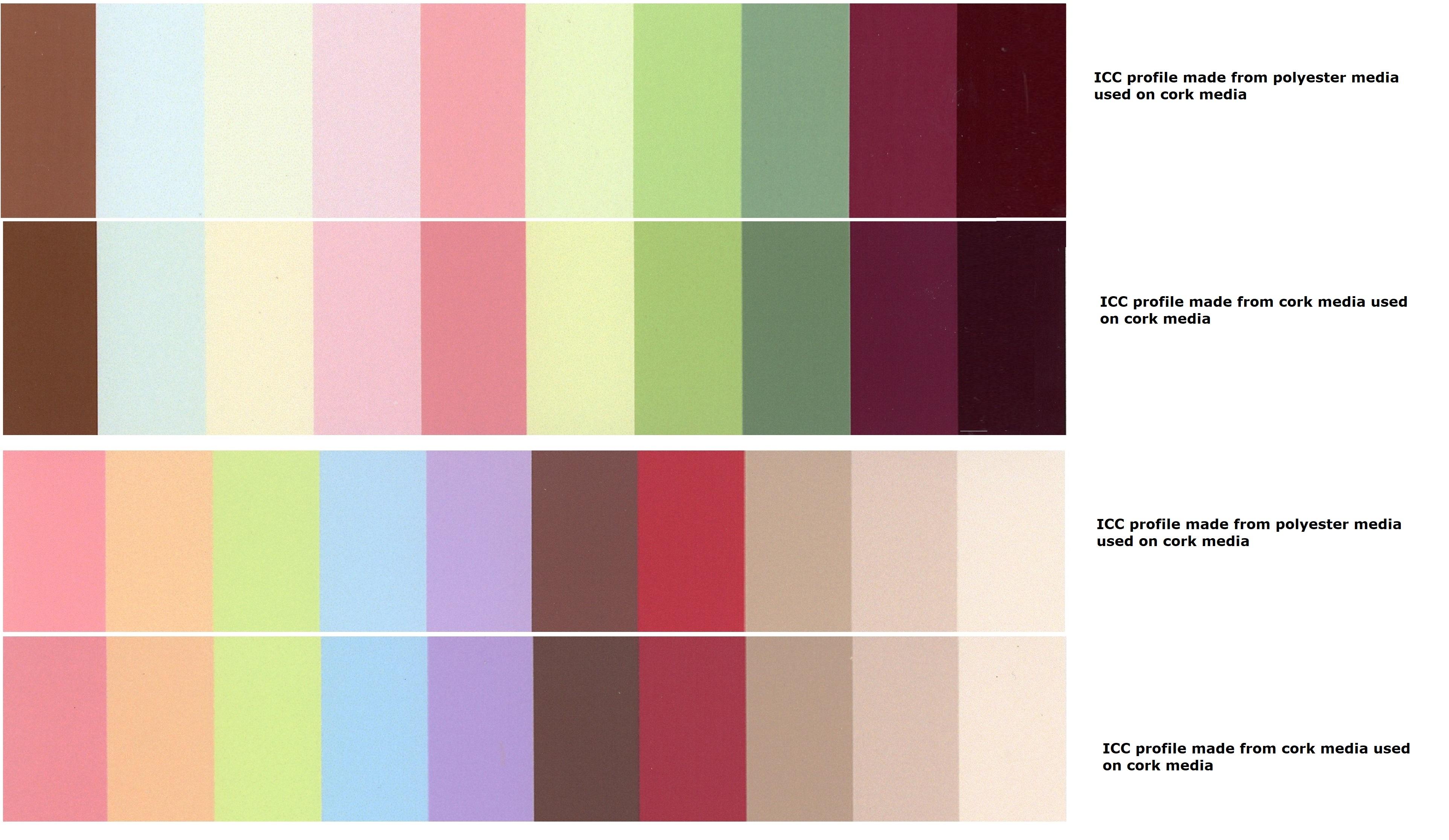

TEST 1

For our colour test charts on this one we are using a using an icc profile created from metal media on ceramic media

On this one we are using a using a metal icc on a ceramic item and the most noticeable differences appear to be blues and blacks when not utilising an icc made on the media type.

TEST 2

For our colour test charts on this one we are using a using an icc profile created from metal media on a Polyester sheet

On this one we are using a using a metal icc on a polyester item and the most noticeable differences appear to be blues and blacks when not utilising an icc made on the media type. -

TEST 3

For our colour test charts on this one we are using a using an icc profile created from metal on a cork / mdf item

On this one we are using a using a metal icc on a mdf / cork item and interesting very little difference except in the blacks which the cork icc on cork is closer to our original image.

We have now released the ciss continuous ink system for Epson Workforce Pro WF-3830DWF,WF-3825DWF Printer here and the video can be found here, It's available with normal dye ink, pigment ink or sublimation ink.

We have now released the ciss continuous ink system for Epson Workforce Pro series including the following printers WF-4820DWF,WF-4825DWF here and the video can be found here, It's available with normal dye ink, pigment ink or sublimation ink.

We have now released the ciss continuous ink system for Epson Workforce Pro WF-7310DTW Printer here and the video can be found here, It's available with normal dye ink, pigment ink or sublimation ink.

Sublimation ICC profiles are created by scanning the media after sublimation for more accurate colours

Why would you create and ICC profile from an item sublimated on ceramics then use that profile when pressing on a different media type ?

A wider range of tones and closer match to the original colours is achieved by using an ICC profile created around the media type you are pressing - custom icc profiles are better if you are trying to colour match a specific design.

ask yourself these questions

1: If you have an icc profile what was it created from ?

2: Are you using it on the same or similar media type ?

3: Are you getting the best results you can from your current setup and supplies ?

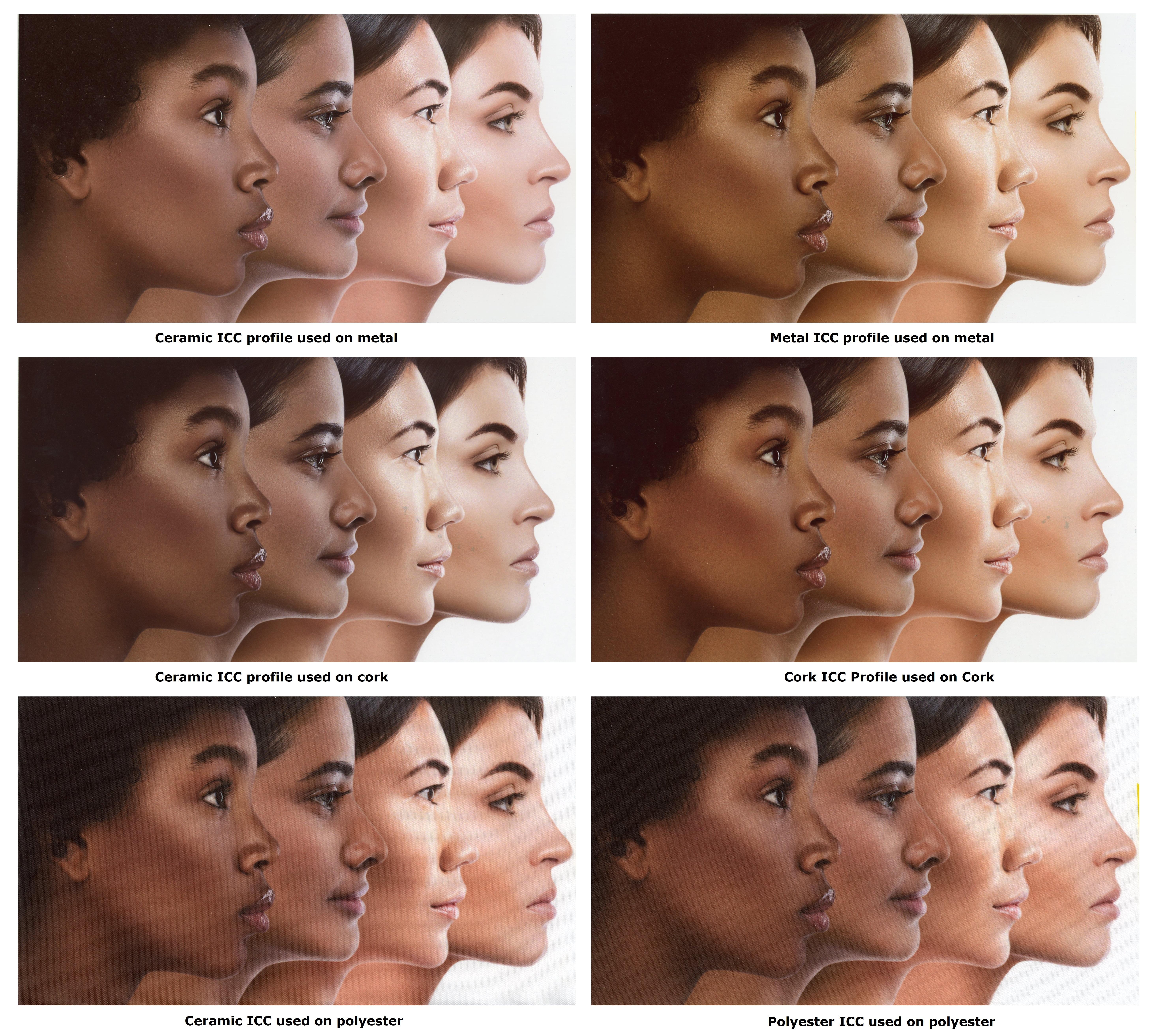

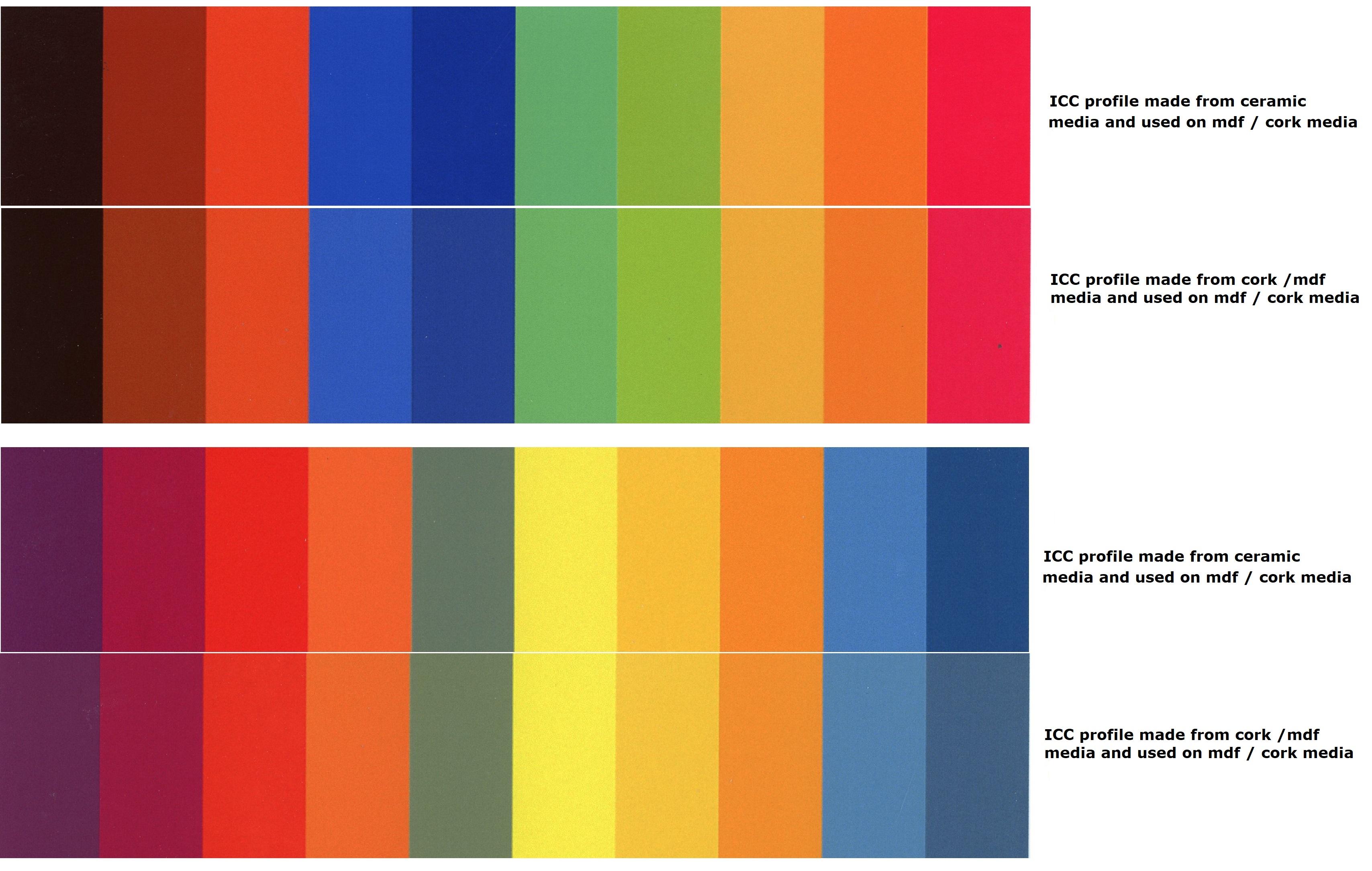

Here are some examples of some images that have been sublimated onto products and then scanned into an image file

The source ICC profile was made on ceramic then we used this profile on other media types and then compared to an icc profile made around the specific media type.

The images do show what we expected - but please bear in mind these are sublimated scanned images - looks much better sitting here looking at the physical products.

TEST 1

For our colour test charts on this one we are using a using an icc profile created from ceramic media on an aluminium sheet

On this one we are using a using a ceramic icc on a metal item and the most noticeable differences on this image are in the deeper blacks / shades with subtle differences in the colours some more than others overall blues and blacks appear to be the most affected colours when not utilising an icc made on the media type.

TEST 2

For our colour test charts on this one we are using a using an icc profile created from ceramic media on a Polyester sheet

On this one we are using a using a ceramic icc on a polyester item and the most noticeable differences on this image are in the blacks / shades ( in person the polyester one is more true ) with subtle differences in the colours some more than others overall blues and blacks appear to be the most affected colours when not utilising an icc made on the media type.

TEST 3

For our colour test charts on this one we are using a using an icc profile created from ceramic media on a cork / mdf item

On this one we are using a using a ceramic icc on a cork /mdf item and the most noticeable differences on this image are in the blue shades

All tests showed darker blues and black when utilising a profile from a different media type but that's not what we are trying to achieve - we are trying to colour match - if we wanted darker blues and blacks we could of just changed our original image